Achieving Remarkable Light Weight in Vegetable Crates: The JunSun Mould Advantage

2025-08-09 | Company News

For plastic vegetable crate manufacturers, reducing weight isn't just desirable – it's essential. Lighter crates significantly cut material costs and boost operational efficiency. As a leading light weight crate mould manufacturer, JunSun Mould provides comprehensive solutions, encompassing everything from initial product design to final mould manufacturing.

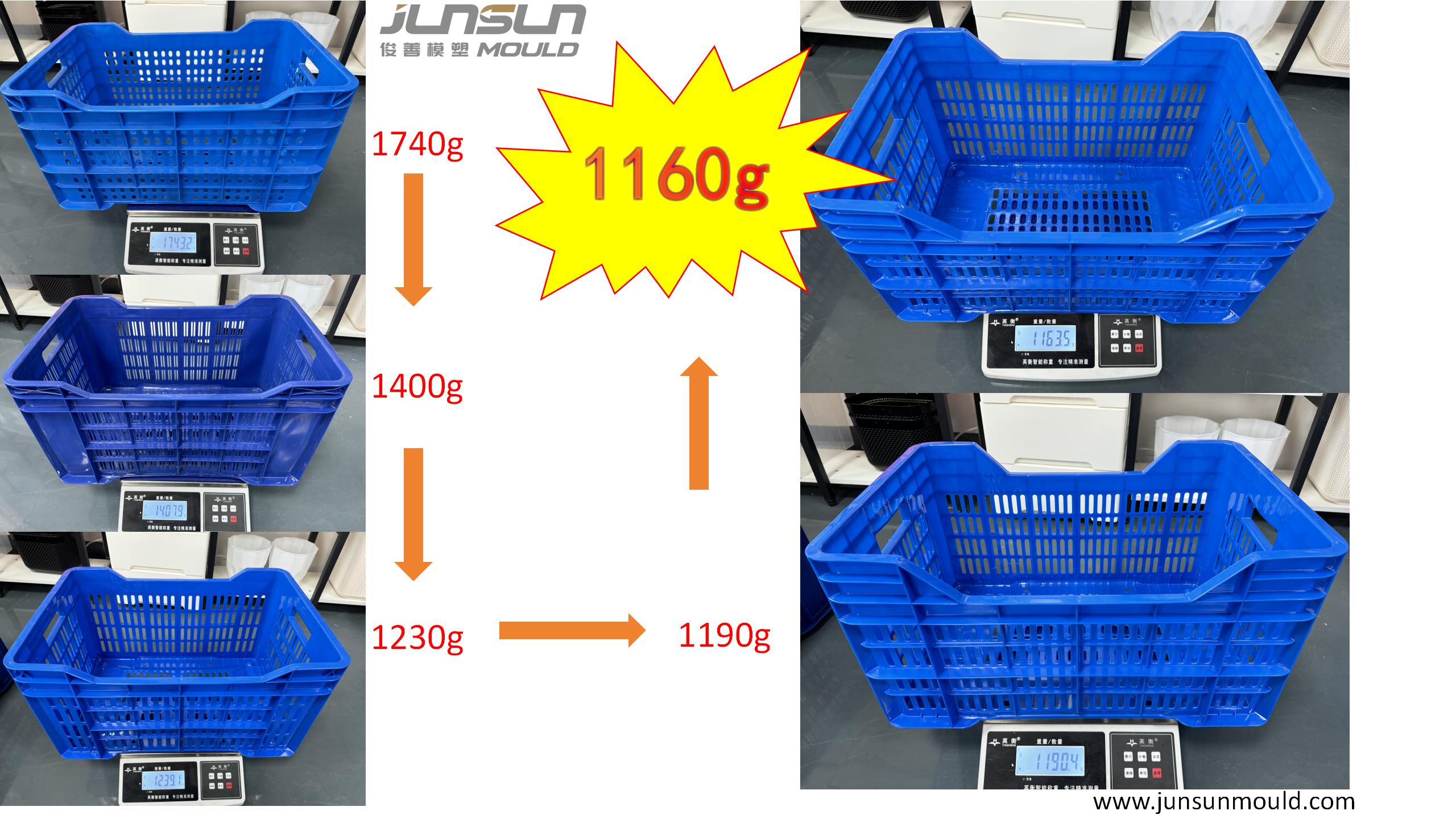

Consider a standard 540x360x290mm crate. While typical weights for this size range between 1.5kg and 2.0kg, JunSun Mould consistently achieves weights of 1.20kg or less for our clients.

Crafting moulds for such lightweight crates demands specialized expertise, focusing on several critical factors:

Precision Product Design: This is the cornerstone of light weight crate mould success. Strategic weight reduction involves carefully analyzing and thinning wall sections, base thickness, and rib structures. Crucially, this must be balanced against ensuring optimal plastic flow during injection. Our designers expertly identify areas suitable for thinning and those requiring reinforcement to guarantee complete filling without defects.

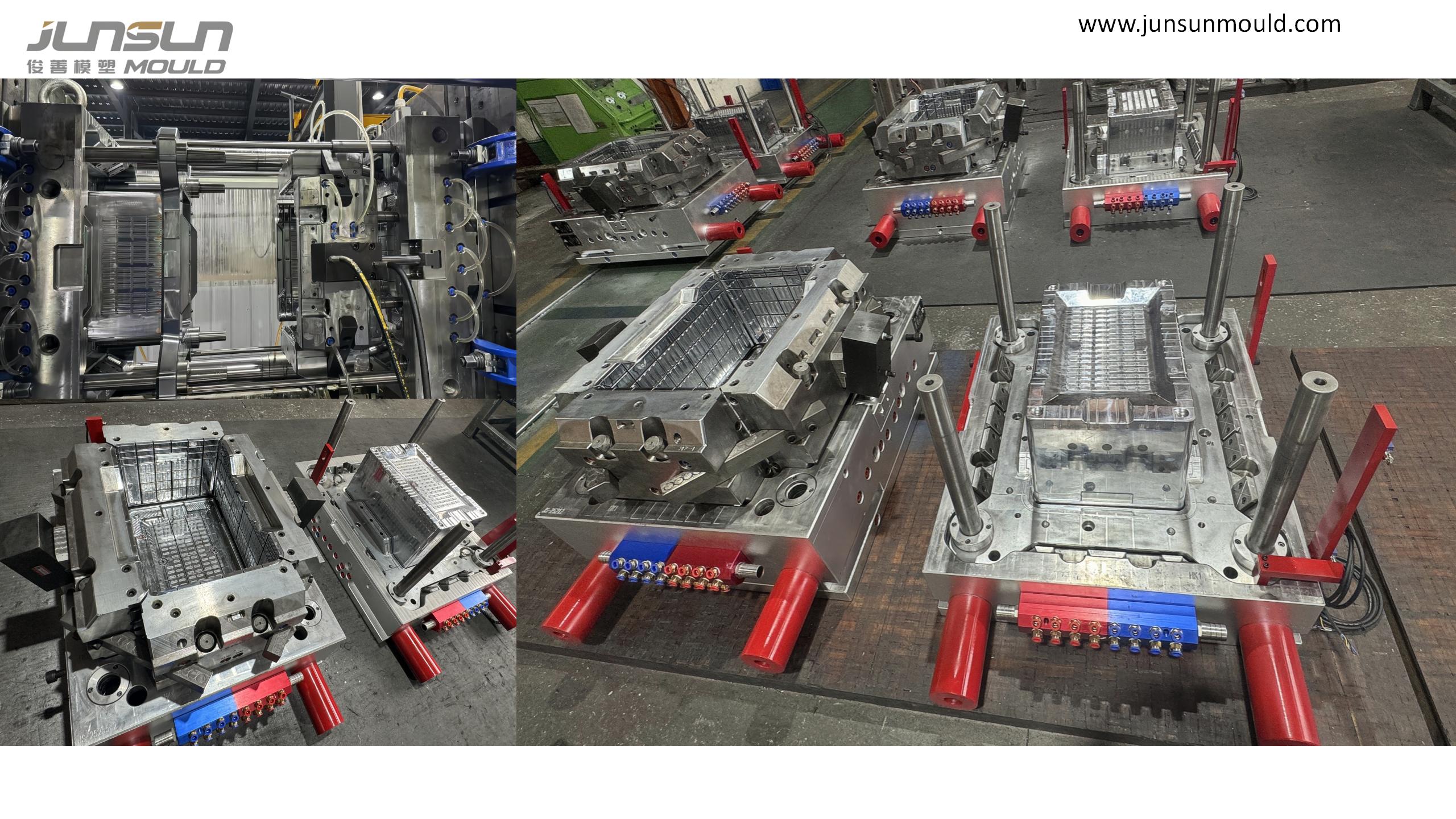

Mandatory Moldflow Analysis: Before machining begins, we conduct thorough Moldflow simulations. This predicts filling behavior and pinpoints the required injection pressure. Our goal is efficient molding without excessive pressure, minimizing operational costs for our customers. For instance, our 1.25kg crate in the 540x360x290mm size typically runs efficiently on a 650-ton machine.

High-Precision Mould Machining: Producing thin-walled crates demands exceptional mould-making accuracy. Standard tolerances are insufficient and can lead to unintended weight increases. JunSun utilizes precision machining to ensure consistent, minimal wall thicknesses.

Optimized Gating Strategy (6 Tips): Unlike standard crate moulds often using 4-gate hot runner systems, we typically employ 6 tips for lightweight designs. This multi-gate approach significantly improves plastic flow, facilitates easier filling of thin sections, and crucially reduces the required clamp force on the injection molding machine. More gates distribute the flow, lowering overall pressure needs.

JunSun Mould has a proven track record as a trusted light weight crate mould manufacturer, delivering tailored solutions for vegetable crates, fruit crates (including mango), fish crates, and disposable crates. Our expertise directly translates to substantial plastic savings and lower production costs for our customers.

Partner with JunSun Mould – your specialist in light weight crate mould manufacturing. Let's discuss how we can optimize your crate design and production.

As a top 5 boiler manufacturers in China, Linkjoint has plenty of accolades from our valued customers due to its sophisticated design, excellent quality, eco-friendly thermal solutions, state-of-the-art equipment and sustaining innovation. Some of latest information about our products and exhibitions we attended are shown as follows.

EV Battery Module Plastic Shell Mold Manufacturer

JunSun Mould specializes in high-quality plastic shell molds for EV battery modules. With proven experience supplying molds for brands like BYD, we deliver tailored solutions for your battery shell mold challenges. Contact us for expert mold design and manufacturing.

Why need mold-flow analysis before mould designing?

Before the current mould design, mold-flow analysis is conducted to analyze the plastic parts themselves, and injection, pressure, and other analyses are performed on the plastic parts before designing the mould. The benefits of conducting mold-flow analysis for moulds are as follows:

How to Create a Quality Plastic Mould?

We often talk about good Plastic Mould and high-quality moulds. So, what kind of mold is a good mold? Let's talk about this topic from the perspectives of a mould manufacturer and a user.