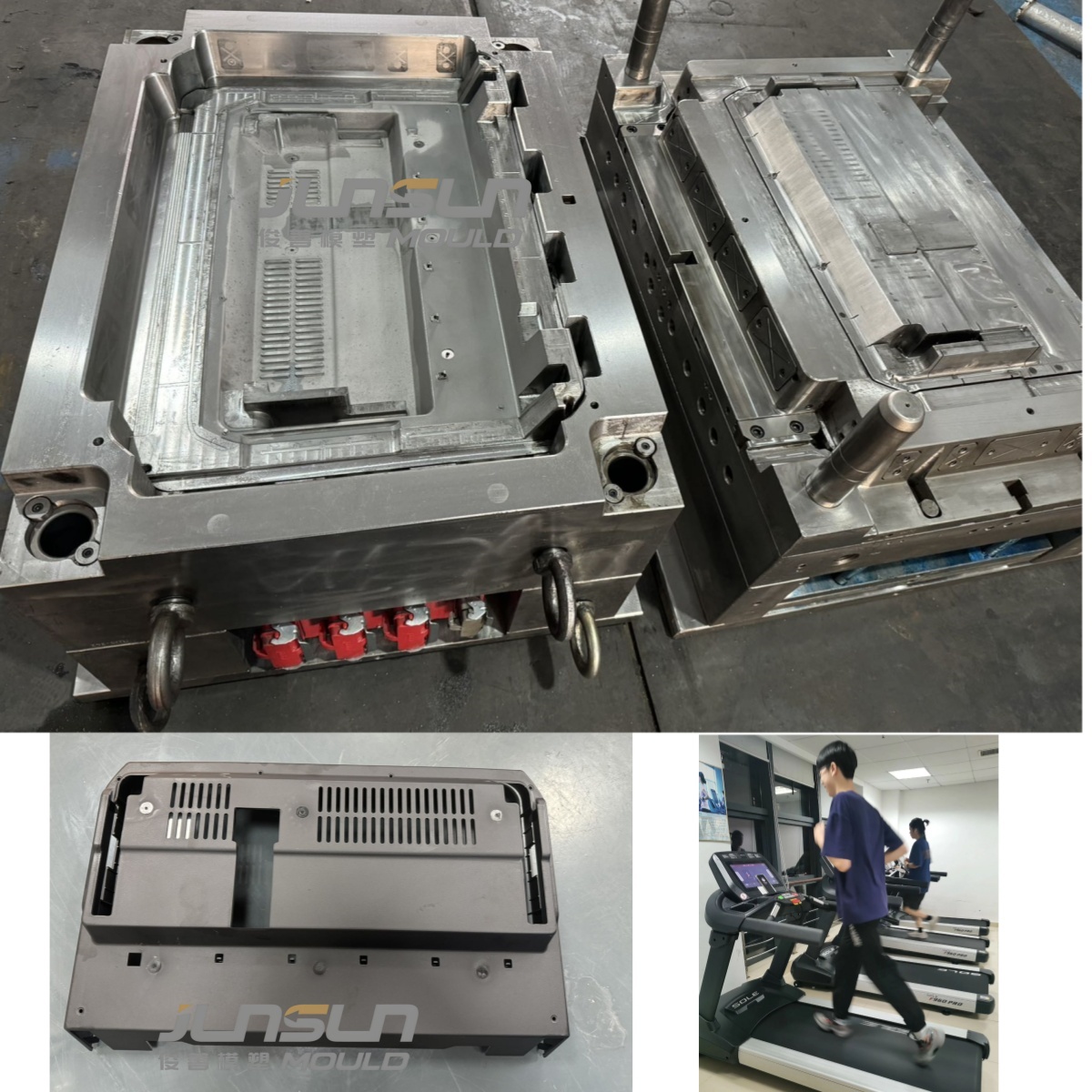

Treadmill Plastic Shell Mold Manufacturer

2025-08-19 | Company News

For over 16 years, JunSun Mould has specialized in the complex art of designing and manufacturing high-performance Treadmill Plastic Shell Molds. This experience isn't just about time; it's about deeply understanding the unique demands of fitness equipment enclosures – where aesthetics, structural integrity, and mass production efficiency collide.

The Foundation: Rigorous Product Analysis

Every successful Treadmill Plastic Shell Mold starts long before steel is cut. We meticulously analyze the treadmill shell's functional requirements:

Structural Load: How much weight and user force must the shell support? Where are mounting points?

Aesthetics & Finish: What surface quality is required (glossy, textured)? Where are critical cosmetic zones?

Assembly & Ergonomics: How does it integrate with other components (console, motor cover, side rails)? Are there handle cutouts or cable routing needs?

Material Selection: Based on impact resistance, UV stability (for home/gym use), and cost targets (PP, ABS, PC-ABS common).

This upfront analysis allows us to optimize the product structure for manufacturability – suggesting reinforcing ribs, uniform wall thickness, and draft angles – ensuring the final mold produces a part that's both strong and visually flawless.

Design Advantages: Precision Cooling & Surface Perfection

The heart of a superior Treadmill Plastic Shell Mold lies in its cooling system design. Large, complex shells are prone to defects like flow marks, weld lines, sink marks, and warpage. Our expertise shines here:

Optimized Cooling Channels: We design conformal or strategically placed cooling lines to ensure rapid, uniform heat extraction. This minimizes cycle time and, crucially, prevents uneven cooling that causes warpage.

Balanced Filling: Advanced mold flow analysis simulates plastic flow, allowing us to position gates and runners optimally. This ensures complete cavity filling under consistent pressure, eliminating flow marks and weak weld lines, guaranteeing a high-quality surface finish right out of the mold.

Robust Construction: Mold components are designed to withstand high injection pressures over thousands of cycles without deflection, ensuring dimensional stability part after part.

Flexibility Through Modularity: Insert Technology

Treadmill designs evolve rapidly. Our molds often incorporate embedded modular inserts within the core and cavity. This allows for:

Cost-Effective Updates: Swapping inserts enables the production of different shell styles (e.g., different console openings, vent patterns, or branding details) using the same base mold.

Faster Changeovers: Reduces downtime between production runs for different treadmill models.

Easier Maintenance & Repair: Damaged sections can be replaced without rebuilding the entire mold.

Enduring Performance: Material & Craftsmanship

A Treadmill Plastic Shell Mold is a significant investment. Ensuring its longevity is paramount:

Premium Mold Steels: Core and cavity blocks are typically machined from high-hardness, pre-hardened steels like 718H, H13, or S136, chosen for wear resistance, polishability, and toughness.

Precision Machining: Utilizing advanced CNC, EDM, and high-speed machining ensures exacting tolerances and perfect surface finishes for the plastic part.

Surface Treatments: Critical components often receive treatments like nitriding or hard chrome plating to enhance surface hardness and corrosion resistance, extending service life significantly. Proper maintenance protocols further ensure these molds reliably produce hundreds of thousands of parts.

Conclusion: The Synergy of Expertise

Creating a truly high-quality Treadmill Plastic Shell Mold isn't a single-step process; it's the culmination of expertise across multiple disciplines. It demands:

Deep product understanding to optimize design for function and moldability.

Advanced mold design and analysis to guarantee filling, cooling, and ejection efficiency, preventing defects.

Strategic material selection for mold longevity and performance.

Precision machining and finishing to achieve the required part quality and mold durability.

Sixteen years of refining this process has taught us that excellence in each phase – from the initial product sketch to the final polished mold component – is essential for delivering a Treadmill Plastic Shell Mold that performs flawlessly, lasts for years, and produces perfect plastic enclosures every single cycle. It's this holistic experience that transforms a mold from a tool into a cornerstone of reliable treadmill manufacturing.

If you are looking for a good Treadmill Plastic Shell Mold Manufacturer, please contact with us.

As a top 5 boiler manufacturers in China, Linkjoint has plenty of accolades from our valued customers due to its sophisticated design, excellent quality, eco-friendly thermal solutions, state-of-the-art equipment and sustaining innovation. Some of latest information about our products and exhibitions we attended are shown as follows.

EV Battery Module Plastic Shell Mold Manufacturer

JunSun Mould specializes in high-quality plastic shell molds for EV battery modules. With proven experience supplying molds for brands like BYD, we deliver tailored solutions for your battery shell mold challenges. Contact us for expert mold design and manufacturing.

Achieving Remarkable Light Weight in Vegetable Crates: The JunSun Mould Advantage

As a leading light weight crate mould manufacturer - JunSun Mould provides comprehensive solutions for crate product design, mould design and mould manufacturing.

Why need mold-flow analysis before mould designing?

Before the current mould design, mold-flow analysis is conducted to analyze the plastic parts themselves, and injection, pressure, and other analyses are performed on the plastic parts before designing the mould. The benefits of conducting mold-flow analysis for moulds are as follows: